Understanding Heat Shrink Connectors: A Comprehensive Guide

Heat shrink connectors are an essential component in the world of electrical wiring and connections. With their ability to provide a secure, insulated connection, they are favored by professionals and DIY enthusiasts alike. These connectors are designed to shrink when exposed to heat, creating a tight seal that protects against moisture, dust, and other environmental factors. Whether you are working on automotive, marine, or home electrical projects, understanding how heat shrink connectors work and their benefits can enhance the durability and reliability of your connections.

In today's fast-paced world, the demand for reliable and robust electrical connections is higher than ever. Heat shrink connectors offer a perfect solution to this need, combining ease of use with outstanding performance. With a variety of sizes and types available, they cater to different applications, ensuring that every connection is not only secure but also protected from potential hazards. This article will delve into the intricacies of heat shrink connectors, exploring their types, applications, and advantages.

As you navigate through this guide, you will discover the significance of heat shrink connectors in various industries and how they can be effectively utilized in your projects. From understanding their construction to learning the best practices for installation, this comprehensive overview aims to equip you with the knowledge needed to make informed decisions regarding your electrical connections.

Read also:Discover Trapp Family Lodge In Stowe Vt A Vermont Getaway

What Are Heat Shrink Connectors?

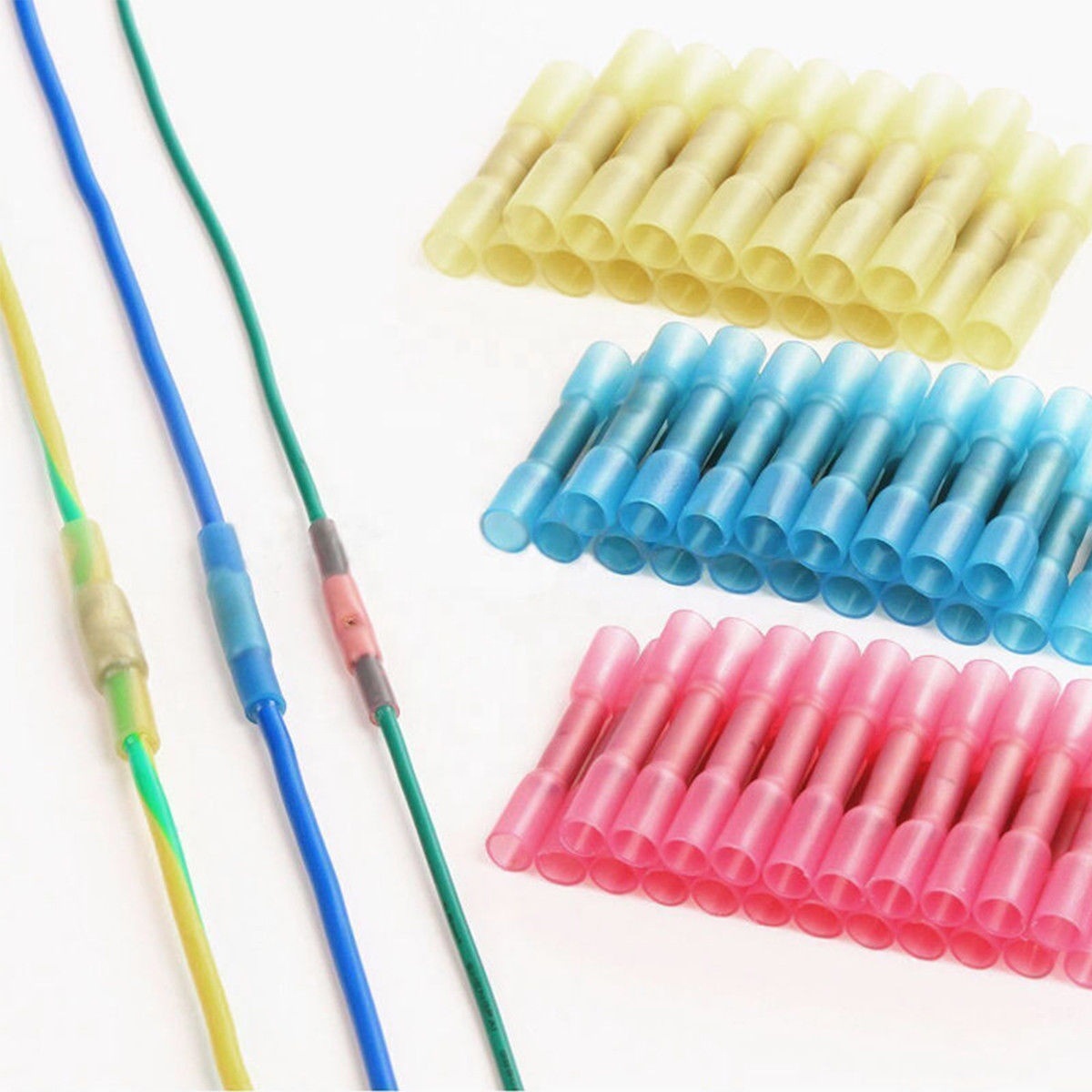

Heat shrink connectors are specialized electrical connectors that come with a layer of heat shrinkable tubing. This tubing is made from thermoplastic material that reduces in size when heated, creating a snug fit around the wire and providing insulation. They are commonly used to join two or more wires together securely.

How Do Heat Shrink Connectors Work?

The operation of heat shrink connectors is relatively simple. When heat is applied, the tubing shrinks tightly around the wire, ensuring a solid connection. This process not only secures the connection but also seals it from moisture and contaminants, which can lead to corrosion or electrical failure.

What Are the Different Types of Heat Shrink Connectors?

- Butt Connectors: Used to connect two wires end-to-end.

- Ring Connectors: Designed for connecting wires to a terminal or screw.

- Splice Connectors: Used to join multiple wires together in a single connection.

- Female and Male Disconnects: Allow for easy disconnection and reconnection of wires.

Why Should You Use Heat Shrink Connectors?

There are several compelling reasons to consider using heat shrink connectors in your electrical projects. They offer a level of protection and reliability that standard connectors may lack. Here are some key advantages:

- Moisture Resistance: Heat shrink connectors create a watertight seal, preventing moisture from entering the connection.

- Durability: The materials used in heat shrink connectors are designed to withstand harsh conditions, making them ideal for automotive and marine applications.

- Easy Installation: With minimal tools required, heat shrink connectors can be installed quickly and efficiently.

- Versatility: They are suitable for a wide range of wire sizes and applications.

How Do You Install Heat Shrink Connectors?

Installing heat shrink connectors is a straightforward process. Here’s a step-by-step guide:

- Prepare the Wires: Strip the ends of the wires that need to be connected.

- Insert the Wires: Place the stripped ends of the wires into the heat shrink connector.

- Crimp the Connector: Use a crimping tool to secure the connection.

- Apply Heat: Use a heat gun to evenly heat the tubing until it shrinks tightly around the wires.

Are There Any Disadvantages to Using Heat Shrink Connectors?

While heat shrink connectors offer numerous benefits, they do have some disadvantages. These may include:

- Cost: Heat shrink connectors can be more expensive than traditional connectors.

- Special Tools Required: A heat gun or similar tool is necessary for installation.

Where Can You Buy Heat Shrink Connectors?

Heat shrink connectors are widely available at various retailers, including:

Read also:The Marvels Of The Chicago Science And Industry Museum A Journey Through Innovation And Discovery

- Hardware Stores: Local hardware stores often carry a selection of heat shrink connectors.

- Online Retailers: Websites like Amazon, eBay, and specialized electrical supply stores offer a wide range of options.

- Automotive Stores: Many automotive parts stores stock heat shrink connectors for vehicle repairs.

Conclusion: Are Heat Shrink Connectors Worth It?

In conclusion, heat shrink connectors are a valuable addition to any electrical toolkit. They provide a reliable, moisture-resistant connection that can withstand various environmental conditions. While they may come at a higher cost compared to traditional connectors, the benefits they offer in terms of durability and performance make them well worth the investment. Whether you are working on automotive repairs, home wiring, or marine applications, heat shrink connectors can enhance the quality and longevity of your electrical connections.

Article Recommendations