Understanding The Jeep Compass Crankshaft Sensor: What You Need To Know

The Jeep Compass, a popular compact SUV, is celebrated for its versatility and performance. Among its many components, the crankshaft sensor plays a critical role in the vehicle's engine management system. This sensor monitors the position and rotational speed of the crankshaft, ensuring that the engine runs smoothly and efficiently. When functioning correctly, the crankshaft sensor contributes to optimal engine performance, improved fuel efficiency, and reduced emissions, making it an essential element of the Jeep Compass's engineering.

However, like any vehicle component, the crankshaft sensor can experience wear and tear over time, leading to potential issues that can affect your Jeep Compass's performance. Drivers may face symptoms such as rough idling, difficulty starting the engine, or even stalling while driving. Understanding how the crankshaft sensor works, its importance, and signs of malfunction can help Jeep Compass owners maintain their vehicles effectively and avoid costly repairs.

In this article, we will delve into the functionality of the Jeep Compass crankshaft sensor, explore common symptoms of failure, and provide guidance on troubleshooting and replacement procedures. Whether you're a seasoned mechanic or a first-time Jeep owner, this comprehensive guide will equip you with valuable knowledge to keep your vehicle running at its best.

Read also:Avril Lavigne 2024 Tour Get Your Tickets Today

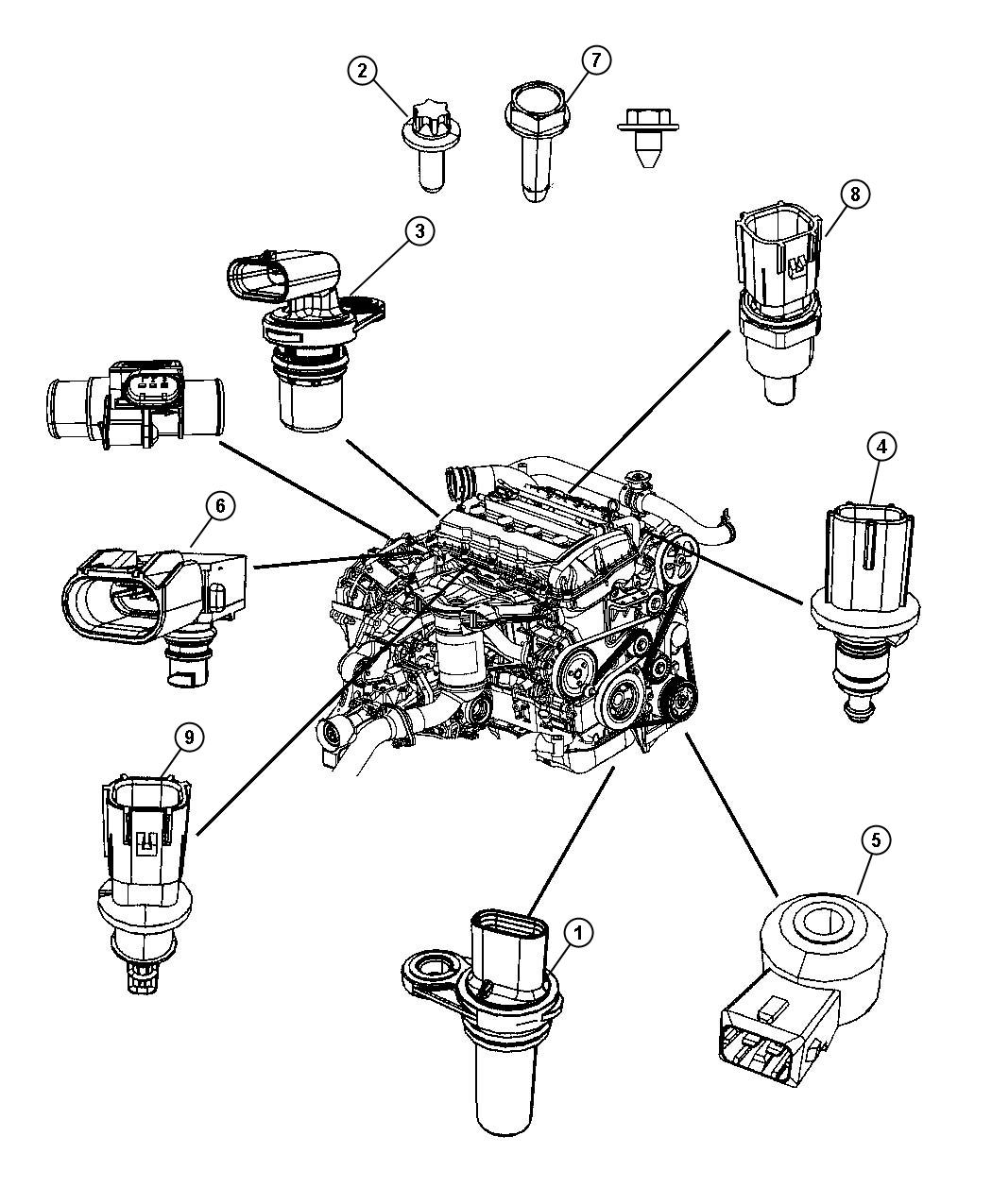

What is the Function of the Jeep Compass Crankshaft Sensor?

The crankshaft sensor is a vital component of the engine management system. Its primary function is to accurately detect the position and speed of the crankshaft, which is essential for the proper timing of fuel injection and ignition. By relaying this information to the engine control unit (ECU), the crankshaft sensor helps ensure that the engine operates efficiently and produces optimal power output.

How Does the Crankshaft Sensor Work?

The crankshaft sensor operates using magnetic induction. It generates a voltage signal as the crankshaft rotates, which is then sent to the ECU. The ECU interprets this signal to determine the crankshaft's position, allowing it to synchronize the timing of fuel injection and ignition. This synchronization is crucial for engine performance, as it ensures that the air-fuel mixture ignites at the right moment for efficient combustion.

What are Common Symptoms of a Failing Crankshaft Sensor?

Recognizing the signs of a failing crankshaft sensor can save you from more significant issues down the line. Some common symptoms include:

- Engine misfires or rough idling

- Difficulty starting the engine

- Stalling while driving

- Check engine light illuminated

If you notice any of these symptoms, it may be time to inspect the crankshaft sensor for potential issues.

How to Troubleshoot Jeep Compass Crankshaft Sensor Issues?

Troubleshooting the crankshaft sensor can be a straightforward process if you have the right tools and knowledge. Here are some steps to follow:

- Check for diagnostic trouble codes (DTCs) using an OBD-II scanner. Look for codes related to the crankshaft sensor.

- Visually inspect the sensor and its wiring for any signs of damage or corrosion.

- Test the sensor's resistance with a multimeter to ensure it is within the manufacturer's specifications.

- Consider performing a crankshaft position sensor relearn procedure if applicable.

What Should You Do if the Crankshaft Sensor is Faulty?

If you determine that the Jeep Compass crankshaft sensor is faulty, it's essential to take action promptly. Here are some steps to follow:

Read also:Finding The Best Tire Services Mavis Tire Near Me

- Purchase a replacement crankshaft sensor compatible with your Jeep Compass model.

- Follow a repair manual or video tutorial for guidance on replacing the sensor.

- After installation, clear any diagnostic trouble codes and conduct a test drive to ensure proper functionality.

Can You Replace the Crankshaft Sensor Yourself?

Many Jeep Compass owners may wonder whether they can replace the crankshaft sensor themselves. The answer depends on your mechanical skills and comfort level with automotive repairs. Replacing the crankshaft sensor can be a DIY project for those with basic mechanical knowledge. However, if you feel uncertain, it's always advisable to seek professional assistance to avoid complications.

What is the Average Cost of Replacing a Jeep Compass Crankshaft Sensor?

Understanding the cost associated with replacing the crankshaft sensor can help you budget for maintenance. The average cost of a crankshaft sensor replacement can vary based on several factors, including:

- Location (dealership vs. independent shop)

- Labor costs in your area

- Type of sensor (OEM vs. aftermarket)

On average, you can expect to pay between $150 and $300 for parts and labor combined.

Conclusion: Keeping Your Jeep Compass Running Smoothly

In conclusion, the Jeep Compass crankshaft sensor is an essential component that significantly impacts engine performance. By understanding its function, recognizing the symptoms of failure, and knowing how to troubleshoot issues, you can effectively maintain your vehicle and ensure it runs smoothly. Whether you decide to take on repairs yourself or seek professional help, being informed will empower you to make the best decisions for your Jeep Compass.

Article Recommendations