Mastering The Art Of Connecting Copper To PVC: A Comprehensive Guide

In the world of plumbing and construction, the ability to connect different materials is essential for maintaining the integrity of a system. One common challenge many individuals face is how to connect copper to PVC. This task is often necessary when upgrading plumbing systems, repairing leaks, or even during new installations. Understanding the best practices and techniques for this connection can help ensure a more efficient and lasting solution.

Connecting copper and PVC can be daunting due to the differences in material properties, expansion rates, and connection methods. However, with the right tools and knowledge, it can be accomplished successfully. This article will guide you through various methods of connecting these two materials, ensuring you have all the information you need to tackle this project with confidence.

Whether you're a seasoned plumber or a DIY enthusiast, knowing how to connect copper to PVC will empower you to take on plumbing projects with ease. From understanding the materials and tools needed to exploring various connection techniques, this guide covers everything you need to know for a successful connection.

Read also:Unmasking The Beau Of The Fifth Column Secrets And Revelations

What Tools Do You Need to Connect Copper to PVC?

To successfully connect copper to PVC, you’ll require a few essential tools to ensure a strong and secure bond. Here’s a list of the necessary items:

- Copper pipe cutter

- PVC pipe cutter or saw

- Deburring tool

- Sandpaper or emery cloth

- Pipe wrench

- Primer and PVC cement

- Epoxy or soldering kit (if needed)

What Are the Different Methods to Connect Copper to PVC?

There are several methods to connect copper to PVC, each with its unique advantages. Here are the most common techniques:

1. Using a Copper to PVC Fitting

This is often the simplest and most reliable method. It involves using a fitting that is specifically designed to transition between copper and PVC. Here’s how to do it:

- Cut the copper pipe and PVC pipe to the desired length.

- Deburr the edges to remove any sharp edges.

- Apply primer to the PVC end and the fitting.

- Apply PVC cement and quickly insert the fitting.

- Allow it to cure as per the manufacturer's instructions.

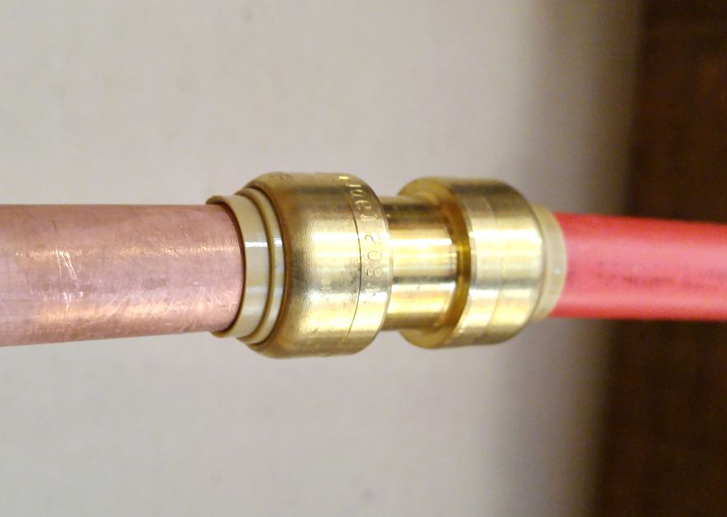

2. Soldering Copper to a Brass Fitting

Another effective method involves soldering copper to a brass fitting, which is then glued to the PVC. Here's the process:

- Prepare the copper pipe by cleaning and sanding it.

- Heat the copper pipe and apply solder.

- Once cooled, connect the brass fitting to the PVC using PVC cement.

Can You Use Epoxy to Connect Copper to PVC?

Yes, epoxy can be used as a method to connect copper to PVC. Here’s how:

- Clean and sand the ends of both pipes.

- Mix the epoxy according to the instructions.

- Apply the epoxy on both ends and press them together.

- Allow it to cure for the recommended time before using.

Epoxy provides a strong bond and can be a great alternative when other methods are not feasible.

Read also:Unleash The Thrill Sun Ski Sports For Ultimate Adventure

What Are the Advantages of Connecting Copper to PVC?

Connecting copper to PVC has several benefits:

- Corrosion Resistance: PVC is resistant to corrosion, which can prolong the lifespan of the plumbing system.

- Cost-Effective: PVC is generally less expensive than copper, making it a more budget-friendly option for plumbing projects.

- Ease of Installation: PVC is lightweight and easier to handle, allowing for quicker installations.

What Are the Common Mistakes to Avoid When Connecting Copper to PVC?

When connecting copper to PVC, avoiding common mistakes can save time and prevent leaks. Here are some pitfalls to avoid:

- Not cleaning the surfaces properly before applying cement or epoxy.

- Using improper fittings that may not create a secure connection.

- Neglecting to follow the manufacturer's instructions for curing time.

How to Ensure a Leak-Free Connection Between Copper and PVC?

To ensure a leak-free connection, follow these tips:

- Double-check all measurements before cutting.

- Use the right type of cement or solder for the materials.

- Allow sufficient curing time before applying pressure.

When Should You Seek Professional Help for Connecting Copper to PVC?

If you are unsure about your ability to connect copper to PVC securely, or if the project is complex, it’s best to seek professional assistance. Additionally, if you encounter any local building codes or regulations that you’re unfamiliar with, a professional can guide you through the requirements.

Conclusion: How to Connect Copper to PVC Successfully

Mastering how to connect copper to PVC is an invaluable skill for anyone involved in plumbing or DIY projects. By understanding the necessary tools, techniques, and common mistakes to avoid, you can ensure a secure and lasting connection. Whether using fittings, soldering, or epoxy, your ability to connect these two materials will enhance your plumbing capabilities and confidence. Always remember to adhere to best practices and seek professional help when necessary for optimal results.

Article Recommendations