Understanding Brake Lining: The Key To Safe Stopping

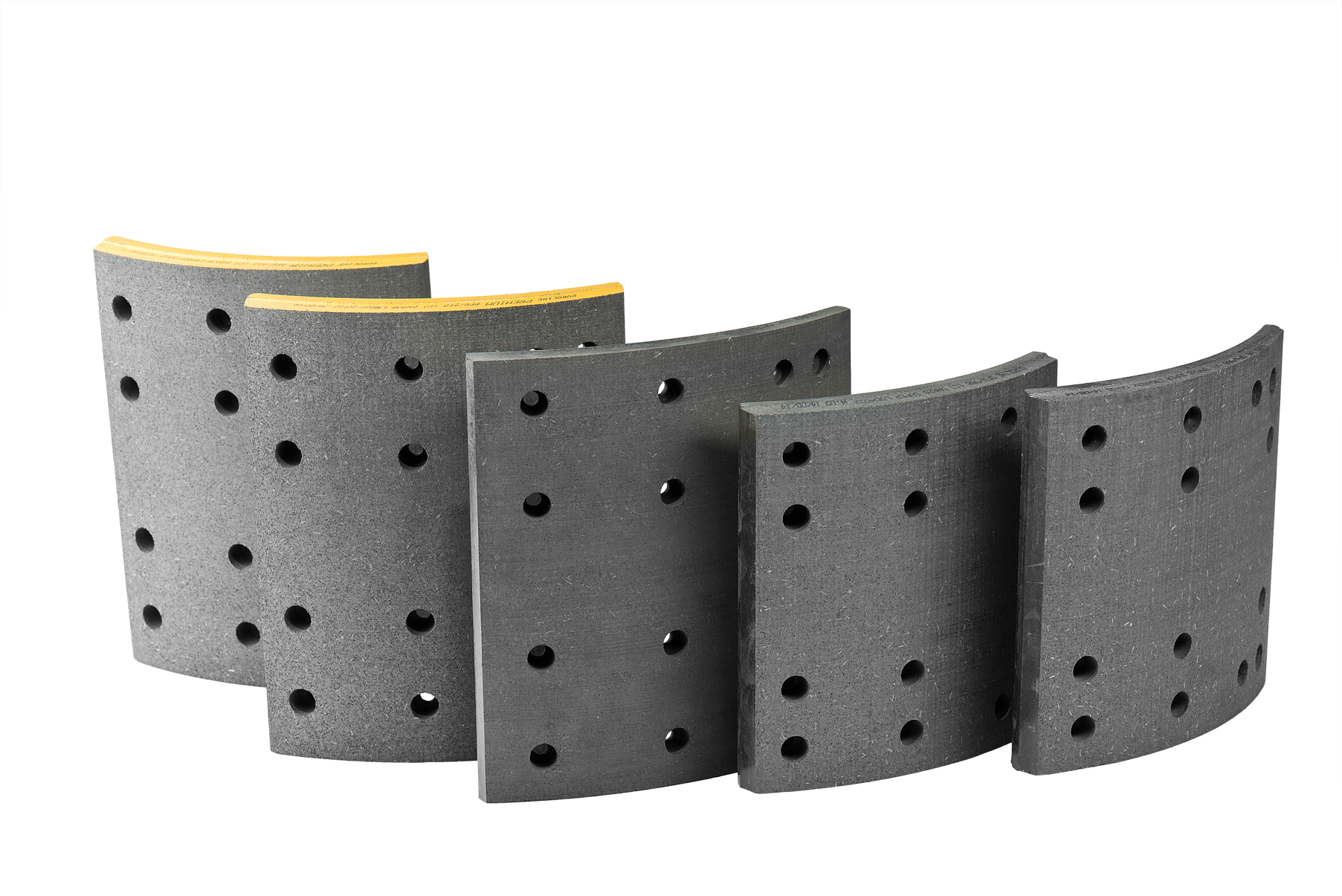

Brake lining plays a critical role in the safety and functionality of vehicles, serving as the material that creates friction against the brake drum or disc. This essential component is often overlooked, but it is vital for effective braking performance. Understanding how brake lining works, its composition, and maintenance can significantly impact vehicle safety and longevity. In this article, we will delve into the fascinating world of brake lining, exploring its purpose, types, and the importance of regular maintenance.

When you press the brake pedal, the brake lining is what allows your vehicle to slow down and come to a stop. This friction material is designed to withstand high temperatures and wear while providing optimal stopping power. As vehicles have evolved, so too has brake technology, leading to various types of brake linings suited for different driving conditions and vehicle types. Knowing the right type of brake lining for your vehicle can enhance performance and safety.

Regular inspection and maintenance of brake lining are crucial. Worn-out brake linings can lead to decreased braking efficiency, increased stopping distances, and potential accidents. By understanding how to maintain and replace your brake lining, you can ensure your vehicle remains safe and reliable on the road. In the subsequent sections, we will answer common questions about brake lining, discuss its types, and provide insights into proper maintenance practices.

Read also:Discover The Best Resorts For Your Next Getaway A Comprehensive Guide

What is Brake Lining Made Of?

Brake lining is typically made from a combination of various materials designed to provide the necessary friction and durability. The most common materials include:

- Asbestos (historically used, now largely banned due to health concerns)

- Organic materials (such as rubber, glass, and resins)

- Metallic compounds (including copper and steel fibers)

- Semi-metallic materials (a blend of organic and metallic components)

Each type has its own benefits and drawbacks, influencing factors such as heat dissipation, noise levels, and wear rates.

How Does Brake Lining Work?

The functioning of brake lining is based on the basic principle of friction. When the brake pedal is pressed, hydraulic pressure forces the brake pads or shoes against the rotor or drum, creating friction that slows the vehicle. The effectiveness of this process relies heavily on the quality and condition of the brake lining.

Why is Regular Brake Lining Maintenance Important?

Regular maintenance of brake lining is essential for several reasons:

- Ensures optimal braking performance

- Prevents costly repairs caused by brake failure

- Enhances overall vehicle safety

- Improves the lifespan of the braking system

Neglecting brake maintenance can lead to significant safety risks and expensive repairs, making it crucial for vehicle owners to stay vigilant.

How Often Should Brake Lining be Inspected?

It is recommended to have your brake lining inspected at least once a year or every 12,000 miles, whichever comes first. However, if you notice any of the following warning signs, it’s essential to have them checked immediately:

Read also:Discover The Ultimate Biking Destination J P Cycles

- Squeaking or squealing noises when braking

- Grinding sounds indicating metal-on-metal contact

- Vibrations or pulsation in the brake pedal

- Decreased responsiveness when braking

What Are the Signs of Worn Brake Lining?

Identifying worn brake linings early can prevent further damage and safety issues. Key signs include:

- Thin or worn brake pads

- Increased stopping distance

- Brake warning light illuminated on the dashboard

- Unusual brake pedal feel (soft or hard)

How to Choose the Right Brake Lining for Your Vehicle?

Selecting the appropriate brake lining depends on various factors, including:

- Vehicle type and weight

- Driving conditions (urban vs. rural)

- Personal driving style (aggressive vs. conservative)

Consulting with a professional mechanic can help in making the best choice for your vehicle's needs.

Can Brake Lining be Repaired or Replaced?

Generally, when brake lining shows signs of significant wear, it needs to be replaced rather than repaired. Replacement involves removing the old lining and installing new pads or shoes, ensuring the braking system functions optimally. Regular inspections can help catch wear early, allowing for timely replacements and preventing more extensive damage to the braking system.

Conclusion: The Importance of Brake Lining

In summary, brake lining is a crucial component of vehicle safety and performance. Understanding its function, maintenance needs, and signs of wear can help vehicle owners make informed decisions. Regular inspections and timely replacements of brake lining can enhance safety, improve braking efficiency, and ultimately prolong the lifespan of the vehicle's braking system. Prioritizing brake maintenance ensures not just your safety, but the safety of others on the road.

Article Recommendations