Exploring The World Of Composite Components: A Comprehensive Guide

Composite components have transformed various industries by offering unique advantages over traditional materials. From aerospace to automotive, the fusion of different materials results in components that are lighter, stronger, and more durable. As industries continue to evolve, understanding the role of composite components becomes crucial for innovation and sustainability.

These materials, often created by combining two or more distinct substances, capitalize on the strengths of each component while minimizing their weaknesses. The versatility of composite components allows for a wide range of applications, from everyday products to advanced engineering solutions. In this article, we will delve into the intricacies of composite components, exploring their properties, benefits, and various applications.

Moreover, as we navigate through the complexities of these materials, we will address common questions related to composite components. Whether you are an industry professional or just curious about the subject, this comprehensive guide aims to provide valuable insights into the fascinating world of composite components.

Read also:The Comprehensive Guide To Sounding Rods Understanding Safety And Techniques

What Are Composite Components?

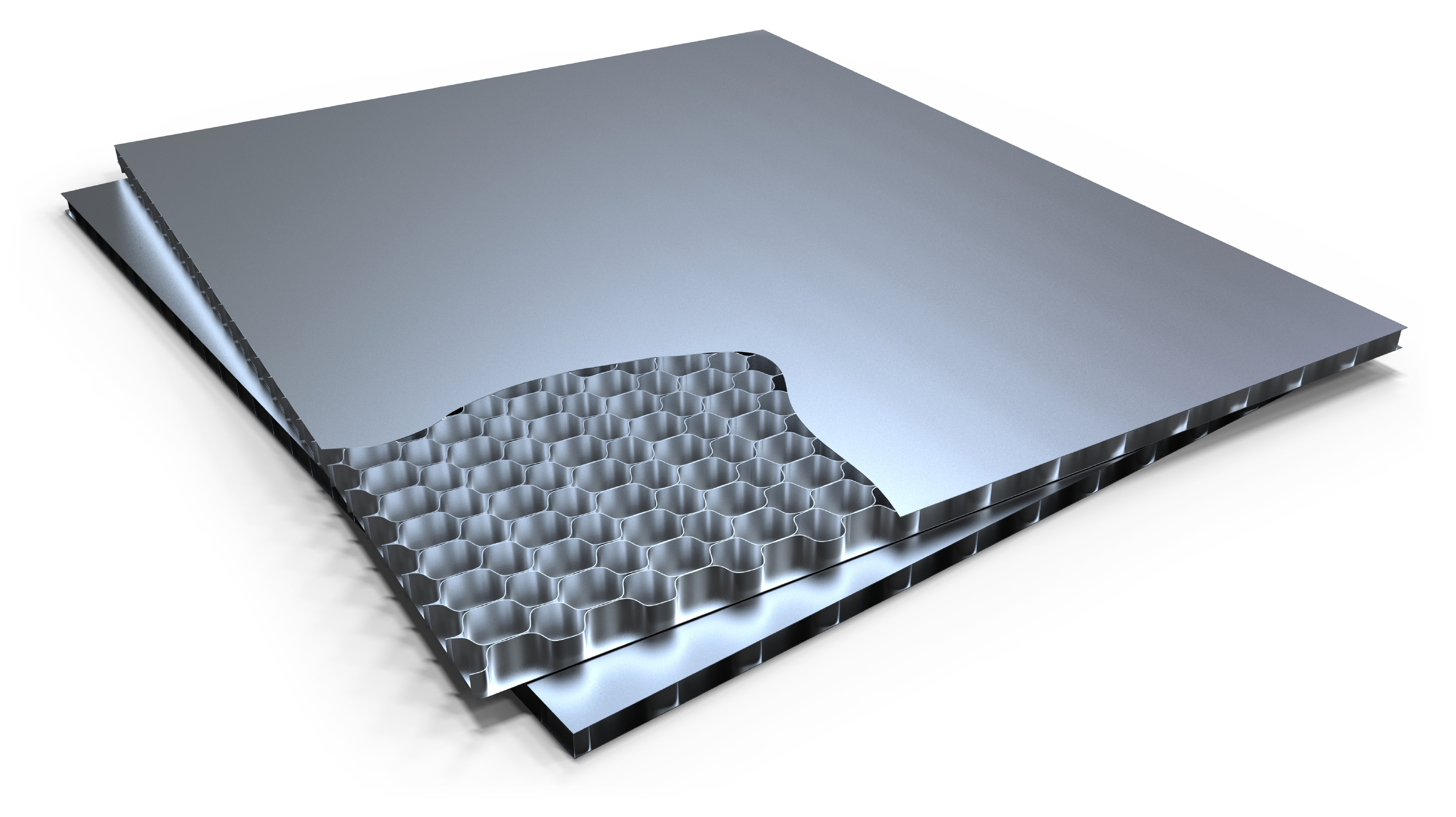

Composite components are materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, these materials produce a new material with enhanced characteristics. Common examples include fiberglass, carbon fiber, and reinforced plastics. The result is a composite that exhibits improved strength, lightweight properties, and resistance to environmental factors.

How Are Composite Components Made?

The manufacturing process for composite components typically involves layering, molding, or bonding different materials together. Key methods include:

- Hand Lay-Up: A manual process where layers of composite material are applied by hand.

- Resin Transfer Molding (RTM): A process where resin is injected into a mold containing the dry fibers.

- Filament Winding: Continuous fibers are wound around a mandrel to create a tubular structure.

- Vacuum Bagging: A technique that uses atmospheric pressure to consolidate composite layers.

What Are the Benefits of Using Composite Components?

The use of composite components offers numerous advantages, including:

- Weight Reduction: Composites are significantly lighter than traditional materials, contributing to improved fuel efficiency in vehicles and aircraft.

- Strength and Durability: Composite components often possess higher strength-to-weight ratios, making them ideal for demanding applications.

- Corrosion Resistance: Many composites resist environmental degradation, extending the lifespan of products.

- Design Flexibility: The ability to mold composites into complex shapes allows for innovative designs.

What Are the Applications of Composite Components?

Composite components find applications across various industries, including:

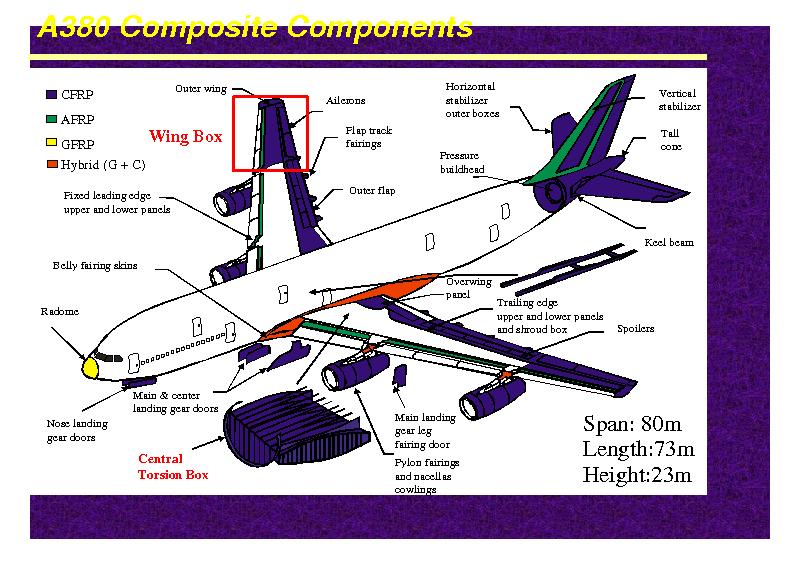

Aerospace and Aviation

In aerospace, composite materials are used to manufacture wings, fuselage sections, and interior components. Their lightweight nature contributes to fuel efficiency and performance.

Automotive Industry

Automakers increasingly use composite components in vehicle structures, body panels, and interior parts to reduce weight and enhance safety.

Read also:How Many Teams Are In The Nfl Your Ultimate Guide To American Footballs League Landscape

Construction and Infrastructure

Composites are also used in building materials, such as beams and panels, due to their strength and resistance to environmental conditions.

Sports Equipment

Many sports goods, including bicycles, tennis rackets, and golf clubs, utilize composite materials for their lightweight and high-performance characteristics.

How Do Composite Components Impact Sustainability?

With increasing focus on sustainability, composite components play a significant role. Their lightweight properties lead to reduced energy consumption and lower emissions in transportation. Additionally, advancements in recycling technologies are making it possible to reclaim and reuse composite materials, further enhancing their environmental benefits.

What Are the Challenges of Composite Components?

Despite the numerous benefits, working with composite components does present challenges, including:

- Cost: The initial investment for composite materials and manufacturing processes can be higher than traditional materials.

- Repairability: Damaged composite components can be more challenging to repair compared to metals.

- Recycling: While advancements are being made, recycling composite materials remains a complex process.

What Is the Future of Composite Components?

The future of composite components looks bright as industries continue to innovate. Ongoing research focuses on developing new materials, improving manufacturing techniques, and enhancing recycling processes. As technology advances, we can expect to see even more applications and benefits from composite components, positioning them as a vital component of modern engineering and design.

Conclusion

In conclusion, composite components are reshaping the landscape of various industries by providing lightweight, strong, and durable solutions. Understanding their properties, benefits, and applications is essential for anyone interested in the future of materials and engineering. As we continue to explore the potential of composite components, we unlock new possibilities for innovation and sustainability.

Article Recommendations