Understanding H7 Hole Tolerance: A Comprehensive Guide

When it comes to precision engineering and manufacturing, tolerances play a crucial role in ensuring parts fit together seamlessly. One such tolerance is the H7 hole tolerance, which is particularly significant in mechanical design. This article aims to delve into the intricacies of H7 hole tolerance, its applications, and its importance in the engineering field. By understanding the H7 tolerance system, engineers can enhance the quality and functionality of their designs, ultimately leading to more reliable and efficient products.

The H7 hole tolerance is part of a standardized system that defines the allowable limits of variation in a hole's diameter. This tolerance is widely used in various industries, including automotive, aerospace, and manufacturing, where precision is paramount. It is essential for engineers and designers to grasp the concept of H7 tolerances to ensure that the components they create will fit together correctly and function as intended.

In this article, we will explore various aspects of H7 hole tolerance, including its definition, applications, and how it compares to other tolerance classes. By the end of this comprehensive guide, readers will have a deeper understanding of why H7 hole tolerance is critical in engineering and how it can impact the overall performance of mechanical systems.

Read also:Dallas House Of Blues A Unique Live Music Experience

What is H7 Hole Tolerance?

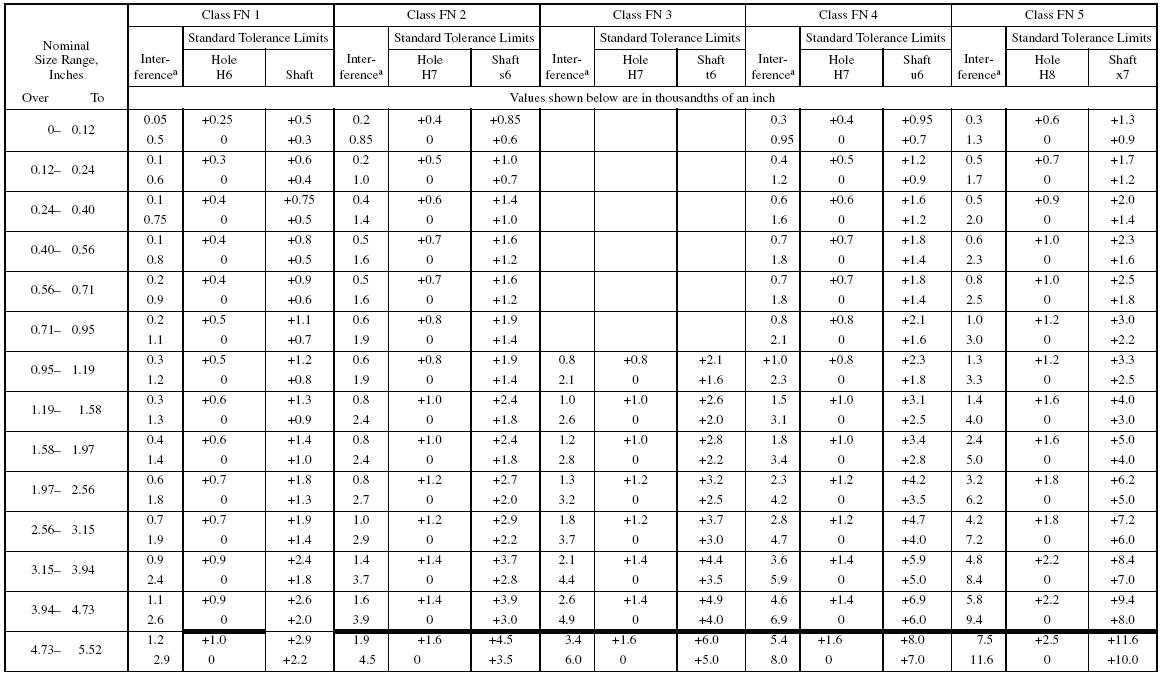

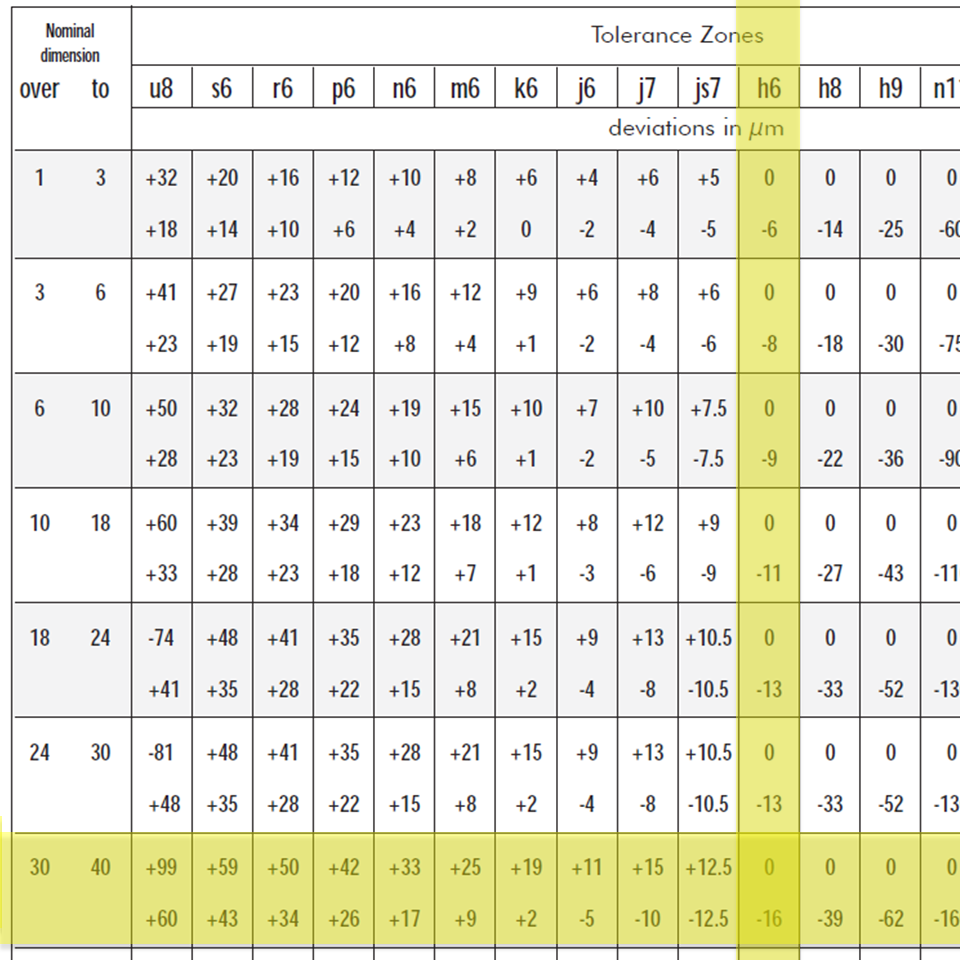

The H7 hole tolerance refers to a specific range of permissible diameters for holes in engineering applications. It is defined by the International Organization for Standardization (ISO) in their ISO 286 standard, which provides guidelines for dimensional tolerances. The "H" in H7 indicates that the hole is a "basic hole," while the number "7" specifies the tolerance grade.

How is H7 Hole Tolerance Measured?

H7 hole tolerance is measured using a combination of the hole's nominal diameter and its tolerance grade. The nominal diameter is the desired size of the hole, while the tolerance grade determines the allowable deviation from that nominal size. For example, if the nominal diameter of a hole is 10 mm, an H7 tolerance might allow for a maximum diameter of 10.018 mm and a minimum of 10.000 mm. This range ensures that the hole will accommodate a corresponding shaft size without compromising fit or function.

What are the Applications of H7 Hole Tolerance?

H7 hole tolerances are widely used in various applications, including:

- Manufacturing of shafts and bearings

- Assembly of mechanical components

- Precision machining

- Automotive and aerospace industries

How Does H7 Hole Tolerance Compare to Other Tolerances?

When discussing tolerances in engineering, it is essential to understand how H7 hole tolerance compares to other tolerance classes. For instance, H6 and H8 tolerances are also common, with H6 being tighter and H8 being looser than H7. This hierarchy of tolerances allows engineers to choose the most suitable option based on their specific requirements.

What Factors Influence the Selection of H7 Hole Tolerance?

Several factors influence the choice of H7 hole tolerance in engineering design:

- The type of fit required (loose, medium, or tight)

- The material properties of the components involved

- Production methods and capabilities

- Cost considerations

How Can Engineers Ensure Accurate H7 Hole Tolerance?

To achieve accurate H7 hole tolerances, engineers can take several measures:

Read also:Infrastructure Forum In Pembroke Ma On September 12th Register Today

- Utilizing precise machining techniques

- Implementing effective quality control measures

- Regularly calibrating measurement tools

- Choosing suitable materials for the application

What are the Benefits of Using H7 Hole Tolerance?

The use of H7 hole tolerance offers numerous benefits, including:

- Improved fit and function of mechanical components

- Enhanced reliability and durability of products

- Reduced likelihood of assembly issues

- Increased efficiency in manufacturing processes

What Challenges Can Arise with H7 Hole Tolerance?

While H7 hole tolerance provides many advantages, there can also be challenges associated with its implementation:

- Potential for increased production costs due to tighter tolerances

- Difficulty in achieving consistent quality during mass production

- Variability in material properties that can affect tolerances

Conclusion: The Importance of H7 Hole Tolerance in Engineering

In conclusion, H7 hole tolerance is an essential aspect of precision engineering that significantly impacts the fit and function of mechanical components. By understanding its applications, benefits, and challenges, engineers can make informed decisions that enhance the overall quality and reliability of their designs. As industries continue to evolve, the importance of H7 hole tolerance will only grow, making it a critical consideration in the engineering field.

Article Recommendations