Mastering The Art Of Joining Plywood: Techniques And Tips

Joining plywood is a fundamental skill for anyone involved in woodworking, construction, or DIY projects. Understanding the various methods of joining plywood not only enhances the strength and durability of your constructions but also allows for greater creativity and flexibility in design. Whether you're building furniture, crafting cabinets, or creating intricate designs, knowing how to effectively join plywood can elevate your projects from ordinary to extraordinary.

When it comes to joining plywood, there are several techniques to consider, each with its unique benefits and challenges. From traditional methods like butt joints and lap joints to modern approaches such as doweling and pocket-hole screws, the selection of the right technique is crucial for achieving the desired result. Additionally, the type of plywood and the specific application will influence your choice of joining method.

In this comprehensive guide, we will explore the ins and outs of joining plywood, including the tools and materials you will need, step-by-step instructions for various techniques, and tips for achieving the best results. Whether you're a seasoned woodworker or a beginner, this article will provide you with valuable insights and practical advice to help you master the art of joining plywood.

Read also:The Comprehensive Guide To Understanding And Using A Windows 10 Key

What Are the Common Methods for Joining Plywood?

When it comes to joining plywood, there are several methods that are commonly used. Here are some of the most popular techniques:

- Butt Joints

- Lap Joints

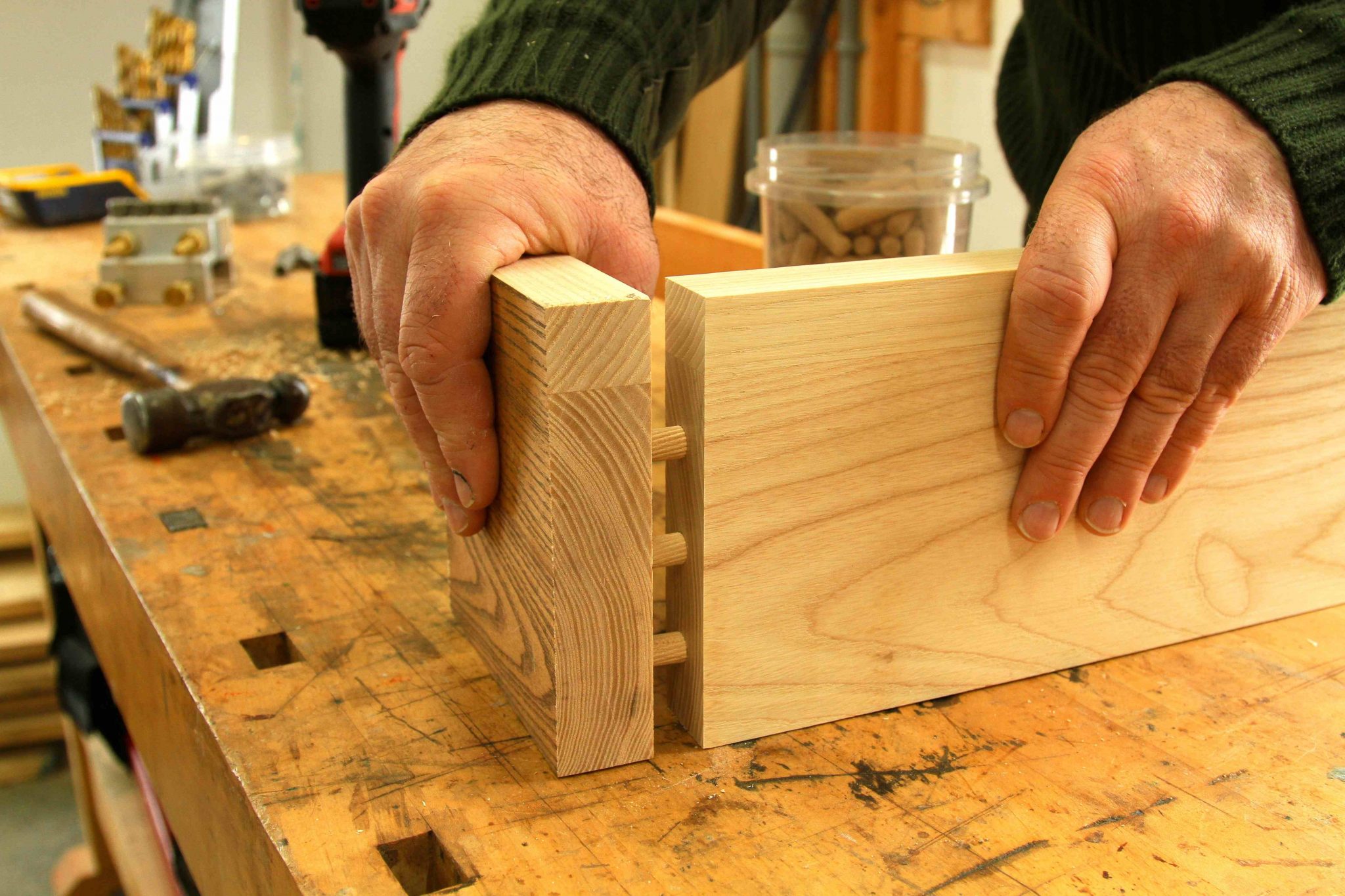

- Dowel Joints

- Pocket-Hole Joints

- Finger Joints

- Biscuits Joints

How Do I Choose the Right Joining Method for My Project?

The choice of joining method will depend on several factors including:

- The strength required for the joint

- The type of plywood being used

- The tools available to you

- The complexity of the project

For example, if you’re working on a heavy-duty construction project, you might opt for a dowel joint for added strength. However, for lighter projects, a simple butt joint may suffice.

What Tools Do I Need for Joining Plywood?

Having the right tools is essential for creating strong and durable joints. Here are some basic tools you should have on hand:

- Table saw or circular saw

- Drill and drill bits

- Screws or nails

- Wood glue

- Clamps

- Measuring tape and square

Can I Use Glue Alone for Joining Plywood?

While glue can be effective for joining plywood, relying solely on glue is typically not recommended for structural joints. Glue works best when used in conjunction with mechanical fasteners such as screws or nails. This combination provides both immediate holding power and long-term strength.

What Are the Best Practices for Joining Plywood?

To ensure strong and lasting joints, consider these best practices:

Read also:Finding The Best Tire Services Mavis Tire Near Me

- Prepare the edges of the plywood by sanding them smooth.

- Apply wood glue evenly and clamp the joint to ensure a tight fit.

- Use screws or nails to reinforce the joint, especially for load-bearing structures.

- Allow adequate drying time for the glue before removing clamps.

How Can I Achieve a Perfect Finish on Joined Plywood?

Once your plywood is joined, achieving a smooth finish is essential for aesthetics and durability. Follow these tips:

- Sand the joints thoroughly to remove any excess glue and imperfections.

- Apply a wood stain or paint to match your desired finish.

- Seal the plywood with a protective finish to enhance longevity.

What Are Some Common Mistakes to Avoid When Joining Plywood?

Here are some common pitfalls to avoid:

- Not using enough clamps, which can lead to misalignment.

- Overusing glue, causing a messy joint.

- Neglecting to sand the edges, resulting in visible seams.

What Should I Know About Plywood Thickness When Joining?

The thickness of the plywood will influence the type of joint you choose. Thicker plywood may require more robust joining methods, while thinner pieces can often be joined with simpler techniques. Always consider the load and stress the joint will encounter in its intended use.

Can Joining Plywood Be a DIY Project?

Absolutely! Joining plywood is a skill that can be easily learned with practice. Start with simple projects and gradually work your way up to more complex designs. Utilize online tutorials and videos for guidance, and don’t be afraid to experiment with different techniques.

In conclusion, mastering the art of joining plywood opens up a world of possibilities for your woodworking projects. By understanding the various methods, tools, and best practices, you can create strong, durable, and visually appealing constructions that stand the test of time. Whether you’re a hobbyist or a professional, the skills you gain from learning how to join plywood will serve you well in all your future endeavors.

Article Recommendations